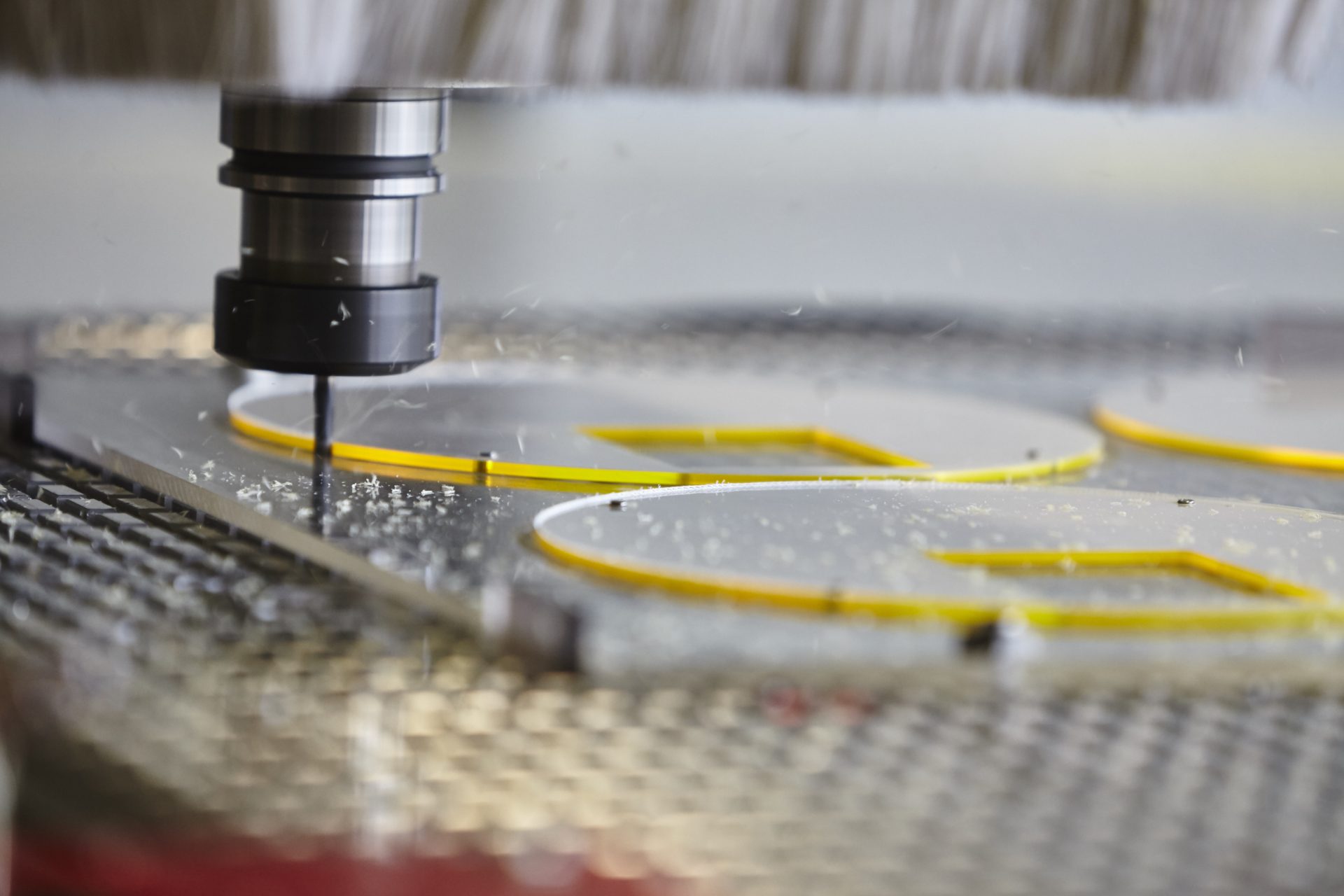

PLASTICS PROCESSING

Our core competence is the manufacturing of sophisticated, customized finished parts. From cutting, via turning and milling, to laser cutting and engraving, through to bonding and deforming, we offer you a functional mixture of a technically most modern machinery and handwork.

The great number of available material and processing technologies provides you a comprehensive spectrum of design, both in series and single-part production.

OUR SERVICES

PROCESSING

- Milling (CNC 3- and 5-axis)

- Bonding

- Deforming (in-house mould making)

- Turning

- Lasering (cutting & engraving)

- Bending (warm and cold)

- Engraving (LED technology)

- Deep-drawing

- Blowing

- Boring

- Polishing

- Tempering

- Cutting

REFINING

- Printing

- Foiling

- Sandblasting

- Lacquering

- Etching

- Vaporizing

WAREHOUSING

The basis for a fast and flexible order processing is our large material warehouse with an extensive stock of thermoplastics. Due to long-term partnerships with all well-known plastic manufacturers we have short-term access to products, which cannot be stocked by ourselves.

CONSULTING

Our application technology gives you support during the product development and in the early design phase. The optimal choice of material, the most functional processing method and a cost minimization analysis are the decisive factors for the success of your product. We would be happy to support you with the market launch of your product.

In cooperation with our long-term system partners we also provide complete solutions.