©2020 KREIDEWEISS. All rights reserved.

Quicklinks: Acrylic glass | Wood | Lightweight materials | Foils

YOU WANT ABSOLUTELY PRECISE FINISHED PARTS?

YOU HAVE COME TO THE RIGHT PLACE!

Whether plastic, wood, metal or foils – thanks to 50 years of experience in the processing of all common materials, we produce sophisticated finished parts according to your wishes, using state-of-the-art machines – up to a workpiece size of 3200 x 2270 mm. Our specialist staff stands by your side every step of the way.

Possible areas of application are:

- Plastic displays and light panels in shop fitting and trade fair construction, e.g. made of acrylic glass

- Large workpieces in furniture and mechanical engineering

- Trophies, decorations and commodities

- Materials used in medical technology

- Foils, signs, guidance systems

- Engrave razor-sharp images

BENEFIT FROM THE ADVANTAGES OF OUR HIGH-POWER LASER TECHNOLOGY

Laser beam processing can be used on various unprinted, printed and also textured materials. Here, it is just the high precision of our laser that makes it so efficient and environmentally friendly.

The camera-assisted cutting processes are true to position and consistent, resulting in smooth edges without any waste. In this way, no material is wasted and no microplastics are released.

BENEFIT FROM THE ADVANTAGES OF OUR HIGH-POWER LASER TECHNOLOGY

Laser beam processing can be used on various unprinted, printed and also textured materials. Here, it is just the high precision of our laser that makes it so efficient and environmentally friendly.

The camera-assisted cutting processes are true to position and consistent, resulting in smooth edges without any waste. In this way, no material is wasted and no microplastics are released.

FIELDS OF APPLICATION

Process acrylic glass and other plastics …

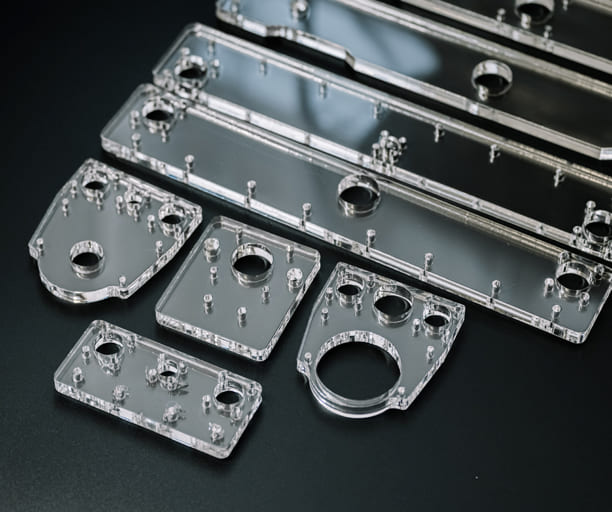

The processing of acrylic glass sheets with the high-power laser is carried out without fixing and in only one working step. Most detailed internal contours are executed precisely without creating a radius. This produces crystal clear, smooth cutting edges without any chips or dust. Additionally, many other plastics can be modified with non-contact laser cutting. Protective foils of other plastic surfaces do not affect our laser.

Process wood …

The contact-free working processes with the high-power laser are a great advantage, especially when processing wood. This results in a minimal waste and breaks are completely avoided. The cutting edges are free from burrs, therefore, a postprocessing is not necessary.

Process lightweight materials …

Suitable for lightweight materials such as foams, cardboard, composites and lightweight construction materials, because the short contact time of the laser means that they are not mechanically stressed. Therefore, laser cutting is particularly suitable here as the quality of the lightweight materials is not reduced even with repeated processing.

Process foils …

Since nothing can stick to the high-power laser, it is optimally suited for processing foils. The cutting edges are sealed immediately without stressing the material mechanically. Cutting the foils with the laser is both very flexible and highly precise – even the smallest recesses are considered.

FAQ

– UP TO WHAT SIZE CAN PLASTIC PLATES BE PROCESSED?

In general, the products to be processed can be 3200 x 2270 mm.

– WHAT IS TO BE CONSIDERED WHEN LASER ENGRAVING WORKPIECES?

Engravings are possible with 256 greyscales with a resolution of up to 1200 dpi. This creates sharp images in 2D or 3D photo quality.